200-4R

PATC Sells GM 200-4R Transmissions, 200-4R Torque Converters and 200-4R Performance Parts. Please browse our catalog for all your 2004R needs!

Showing 1–16 of 250 results

-

Dodge / GM Ratio Adapter, Select Speed Up Rate

$ 149.00 Select options -

* 200-4R Speedometer Driven Gear. Comes in 26 to 31 tooth gear count.

$ 17.00 Select options -

Dodge / GM Ratio Adapter, Select Slow Down Percent

$ 149.00 Select options -

* 700R4 Speedometer Gear Housing Inner Seal. Also fits BOP TH350 / 200-4R / TH400 PG

$ 1.60 Add to cart -

* A64533, 700R4 / 4L60E / 2004R Pump Vane, 1981-Up.

$ 1.00 Add to cart -

* Ratio Adapter Small Part Kit

$ 19.00 Add to cart -

* TCS 373405, 200-4R / 4L60E / 700R4 13 Vane Billet Steel Pump Rotor

$ 210.00 Add to cart -

Sonnax AS1-01K, 2004R / 4L60 / AOD / AXOD / TH200 / TH200C TV Cable Corrector Kit, (1 set)

$ 7.00 Add to cart -

* Speedometer Crimp-on Square Drive Cable End, Number 105. (one piece)

$ 9.00 Select options -

* 2004R / TH350 / 4L60E / 700R4 Plastic Dust Cover

$ 25.00 Add to cart -

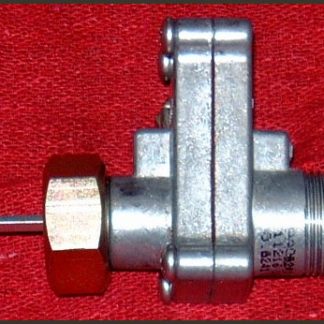

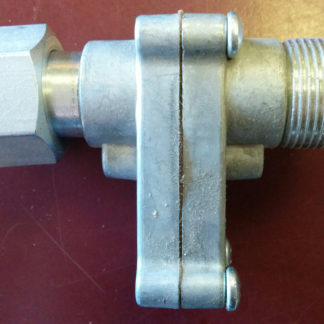

* 200-4R Billet Aluminum Speedometer Housing

$ 50.00 Add to cart -

* 200-4R Speedometer Drive Gear – 10 Tooth

$ 55.00 Add to cart -

* Chevy TH350 / 200-4R Speedometer Housing Retainer (one retainer), #68R

$ 7.00 Add to cart -

Custom Ratio Adapter, Speed Up or Slow Down your Speedometer, Call 1-888-201-2066

$ 189.00 Select options -

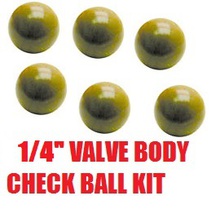

Sonnax 10000-08, Torlon CheckBall

$ 8.00 Add to cart -

* 83 Inch Speedometer Cable 5/8 nut on top 7/8 nut on bottom

$ 45.00 Add to cart

Showing 1–16 of 250 results